Featured Burrs

View all

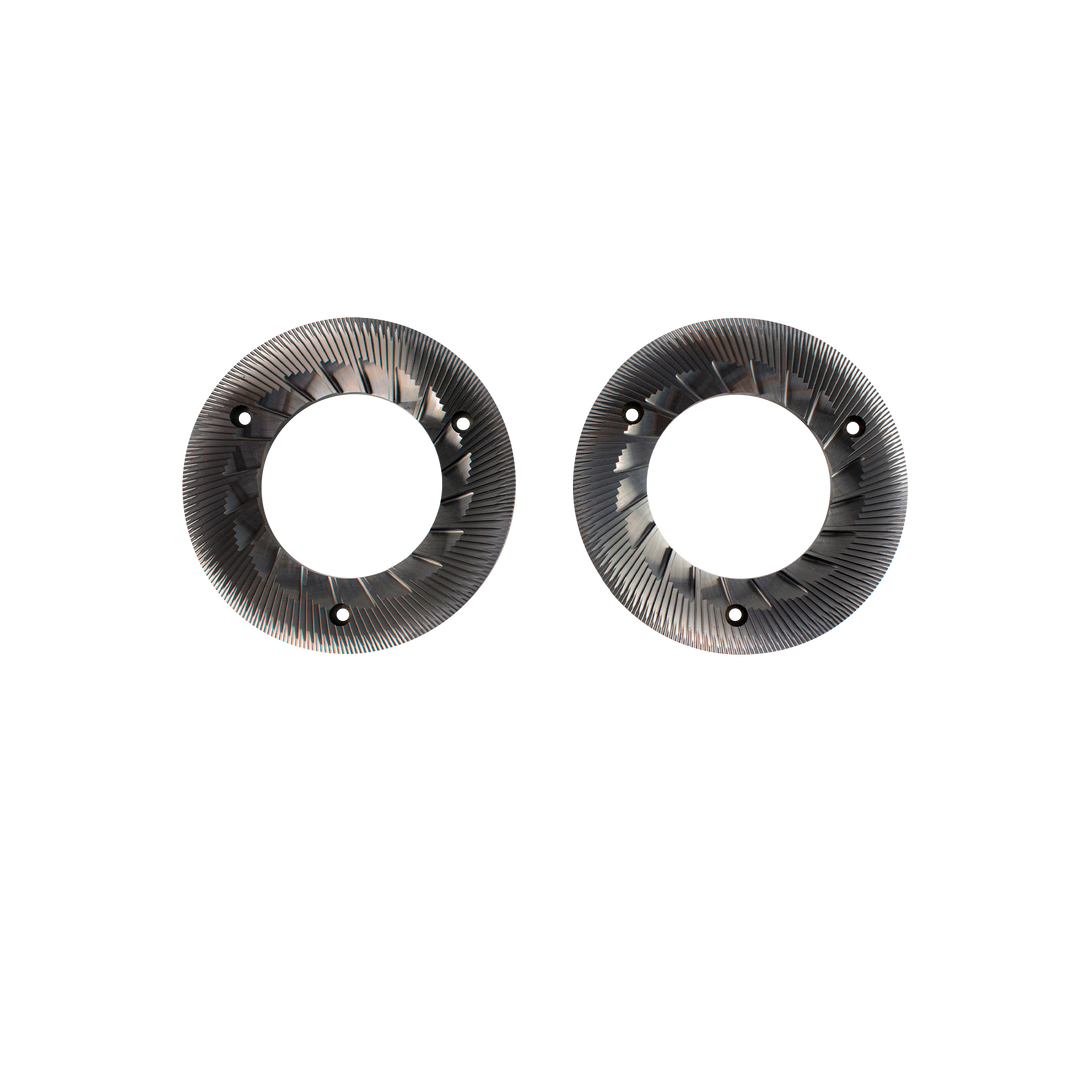

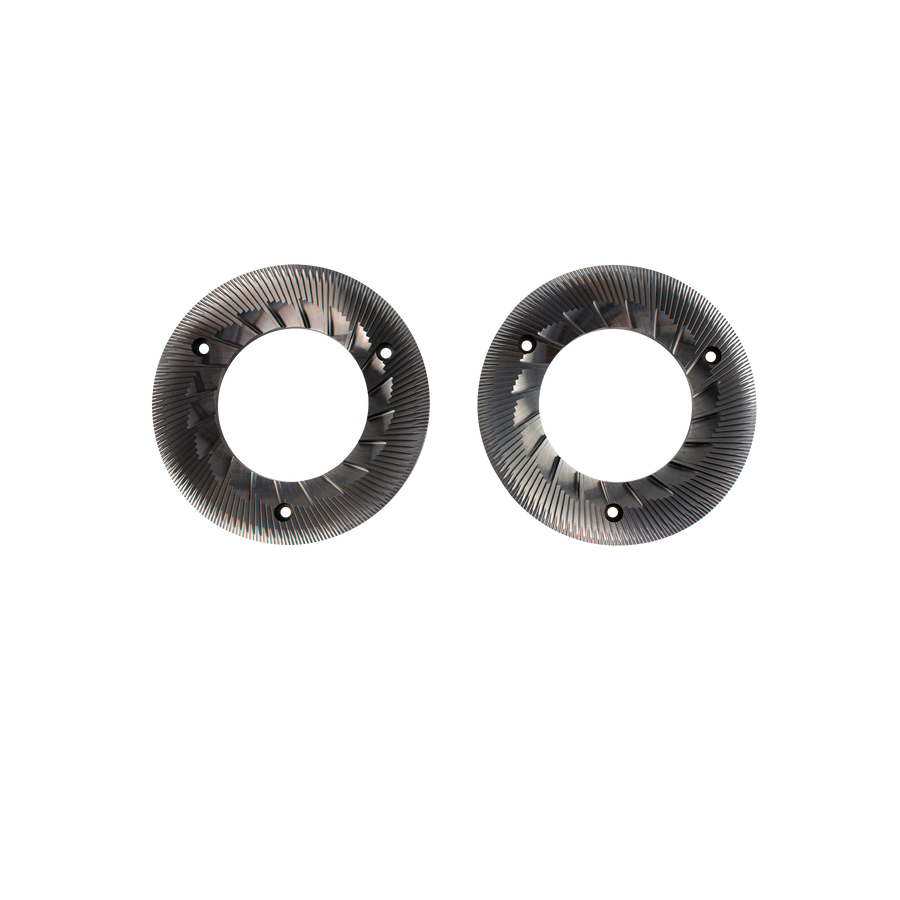

SPECIAL STEEL

Flat Burrs

CHF 000

CHF 0.00

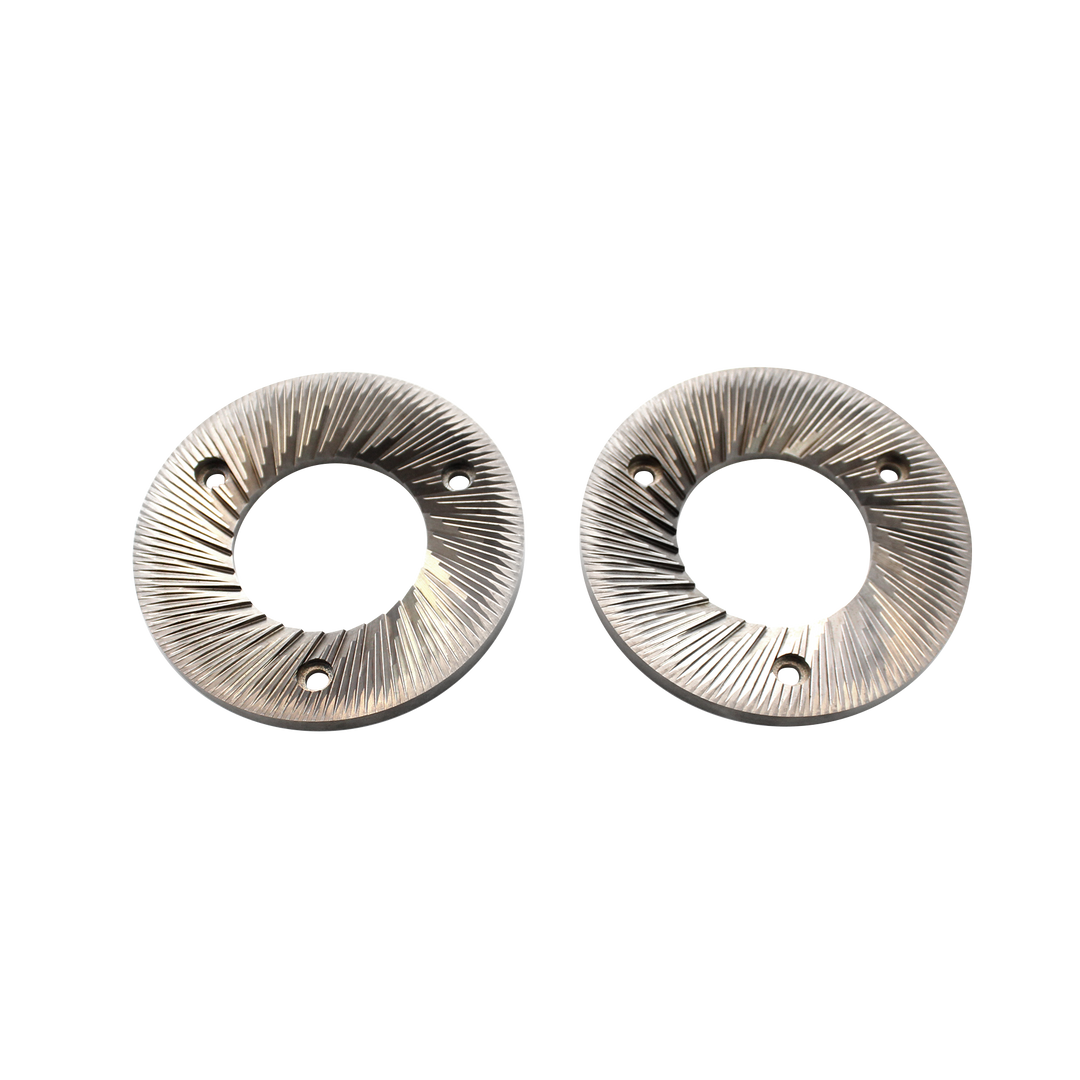

CAST STEEL

Flat Burrs

CHF 000

CHF 0.00

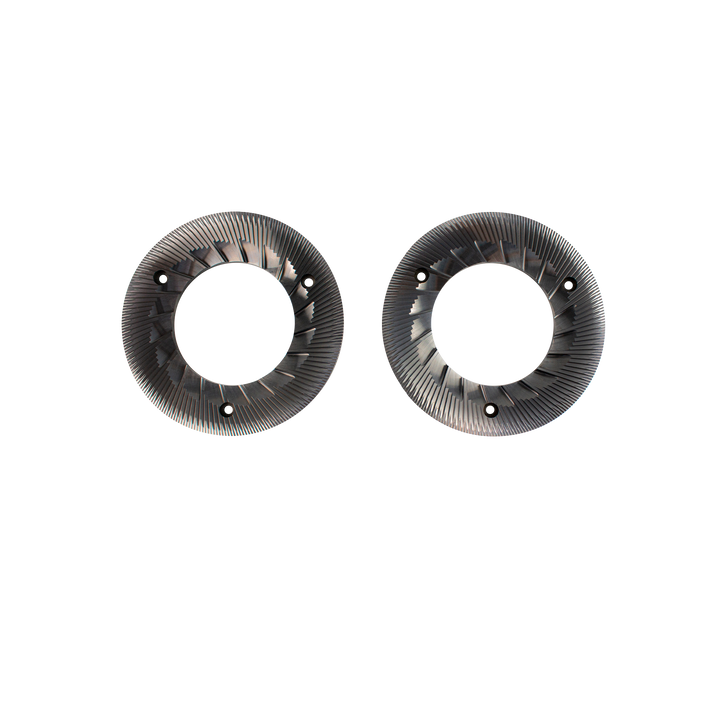

CERAMIC

Flat Burrs

CHF 000

CHF 0.00

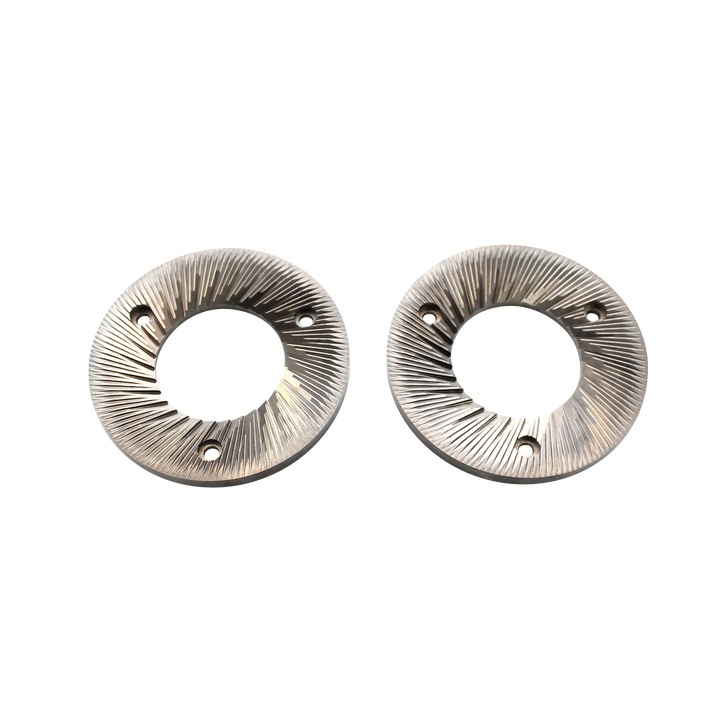

TUNGSTEN CARBIDE

Flat Burrs

CHF 000

CHF 0.00

GRINDZ

Grinder Cleaner

CHF 000

CHF 0.00